SAVING ENERGY IN GLASS LAMINATION

SAVING ENERGY IN GLASS LAMINATION

While a laminating line rarely is the largest energy consumer in your factory, modern technology brings significant savings.

The easiest way to save energy in the laminating process is to replace a traditional infrared heater furnace with a full convection furnace. Glass processors typically report energy savings of at least 50% after a furnace modernization. With today’s energy prices, this can easily amount to tens of thousands of euros in annual energy savings.

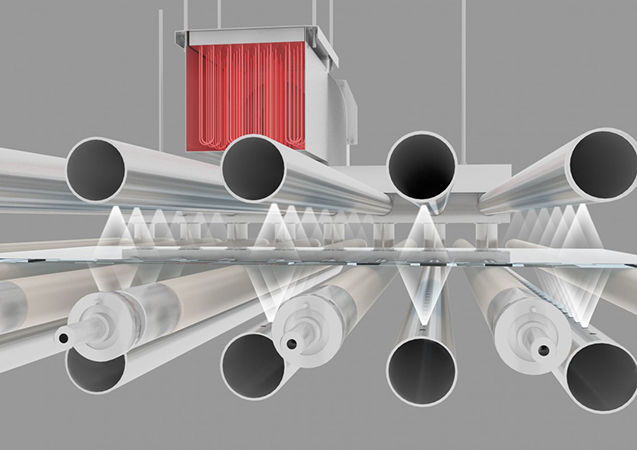

FULL CONVECTION VS RADIATION

Since closed-loop convection minimizes energy losses in the process, full convection-based furnaces use much less energy than radiation-based furnaces.

CUTTING DOWN ENERGY COSTS

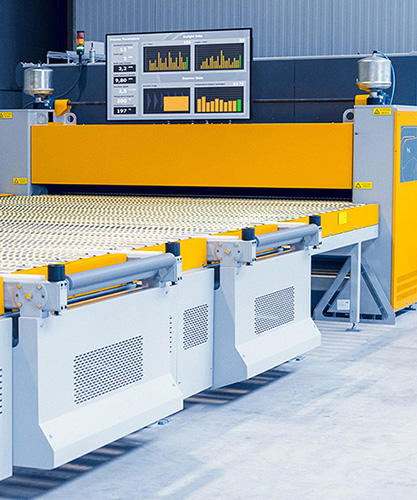

WHAT IS A PROL-ZONE UPGRADE?

ProL-zone is a quick and easy way to replace an outdated laminating line heating chamber to gain energy savings – without acquiring a completely new line.

CASE EXAMPLE: GLASEKSPERTEN

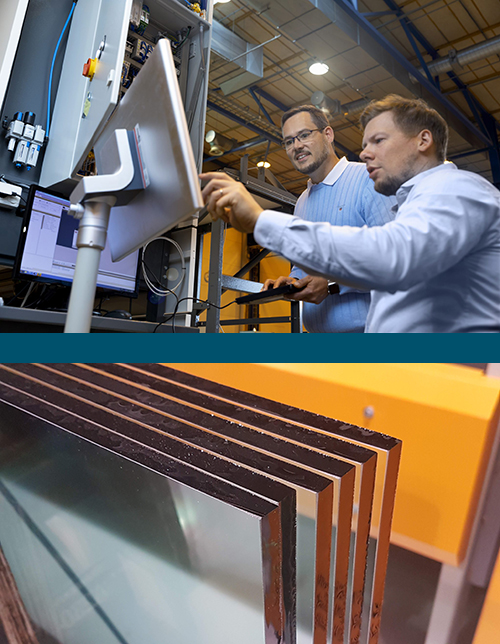

ProL-zone heating chamber upgrade for the existing 5-year-old line

Independent Glass, UK

“The entire upgrade project with Glaston’s ProL-zone went very smoothly. We’ve now been able to increase our laminating capacity, run the line with flexibility and ease – and lower our energy consumption.”

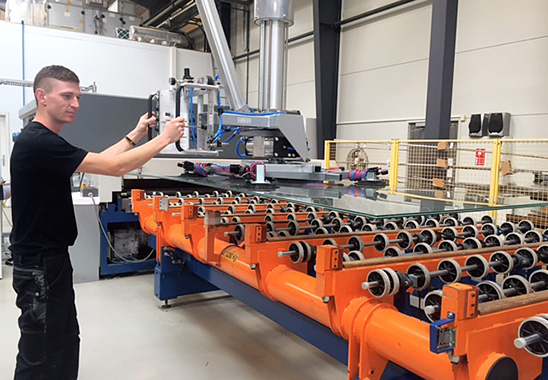

Read moreJaakko-Tuote, Finland

“The idea of investing in Glaston’s ProL-zone laminating furnace started as an R&D project for us. The goal for us is to raise capacity and improve our lamination line’s energy efficiency. We’re starting a demanding safety glass project and will use ProL-zone for that.”

Read moreBUYER’S GUIDE

This guide is a must-read for all of you considering a laminating line acquisition. It includes everything from lamination basics to common pitfalls in laminating projects. Avoid the mistakes of others and make your own project successful.

Read more