TPS® – THE MOST MODERN SOLUTION FOR INSULATING GLASS MANUFACTURING

TPS® – THE MOST MODERN SOLUTION FOR INSULATING GLASS MANUFACTURING

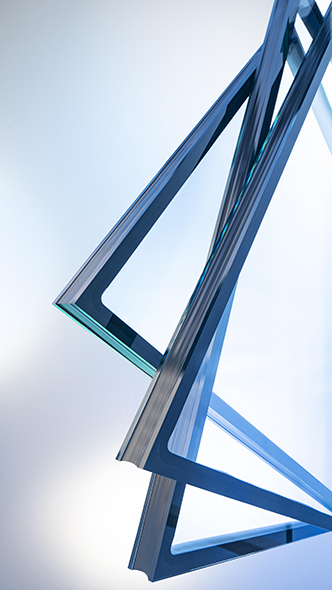

What is TPS®?

TPS® is the most modern and flexible solution for insulating glass manufacturing. Unlike conventional technologies, TPS® allows applying the thermoplastic spacer material directly onto the glass plate.

Glaston launched this technology into the market in 1994. To date, there are over 150 TPS® systems in use globally – and several million TPS® IG units installed.

With TPS®, separate IG production processes, such as bending, sawing, connecting, filling and butyl coating, are no longer necessary. Plus, spacer widths can be changed automatically without manual intervention.

What is more, TPS® simplifies organization within the factory since even mixed production can be flexibly manufactured on a single line in an endless mode – without any loss of time.

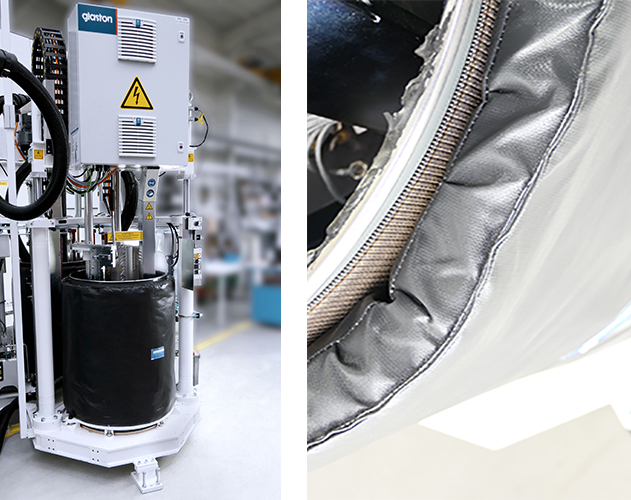

New drum pump system

NEW DRUM TROLLEY SYSTEM

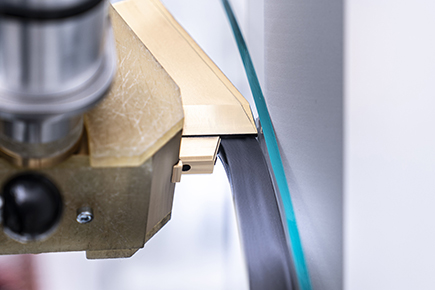

GEAR PUMP TECHNOLOGY

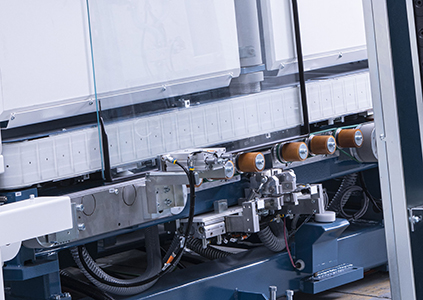

VACUUM SUCTION BELT

bevel joint

And more

Glas Herzog, Germany

“We have a great deal of confidence in our supplier,” says Andreas Herzog, Sr., Managing Director of Glas Herzog. “Our cooperation with former Bystronic glass – and now Glaston – is just as you would want it to be as a customer. In fact, we’re one of their oldest customers – 44 years and counting.”

Read moreGlas Dreisbusch, Germany

“The idea of a special U-shaped design to fit our confined space was created over lunch by my son Maximillian Dreisbusch and two Glaston service engineers. I think this says everything about our close and collaborative partnership with Glaston,” says Thomas Dreisbusch, Managing Director of Glas Dreisbusch.

Read moreBuyer's guide

This guide is a must read for all in the process of acquiring or thinking of acquiring an insulating glass (IG) manufacturing line. It includes everything from basics of IG to common pitfalls in the IG projects.

Learn from mistakes that have already been made by somebody else to make your own project successful.